WHY WORK WITH US

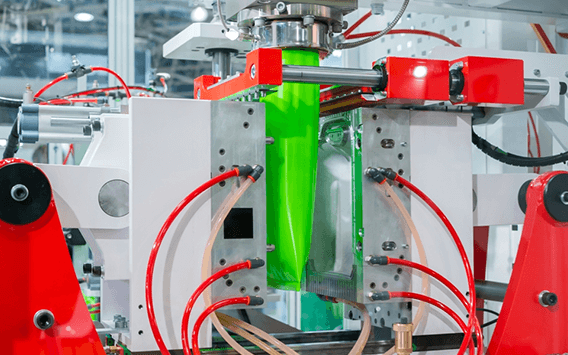

In extrusion blow moulding (EBM), plastic is melted and extruded into a hollow tube (a parison). This parison is then captured by closing it into a cooled metal mold. Air is then blown into the parison, inflating it into the shape of the hollow bottle, container, or part. After the plastic has cooled sufficiently, the mold is opened and the part is ejected.

Examples of parts made by the EBM process: most polyethylene hollow products, milk bottles, shampoo bottles, automotive ducting, watering cans, and hollow industrial parts such as drums.

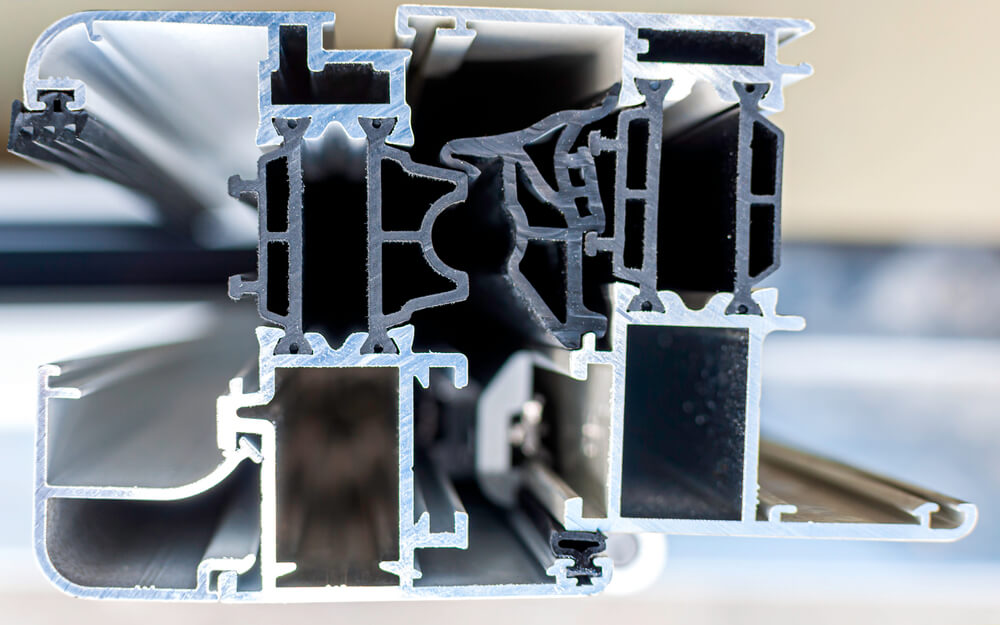

The extruder is also used for extruding beams and PVC/wPVC profile for doors and windows.